News

Site Editor

Site

https://medke.usa18.wondercdn.com/uploads/image/63d7b0e4f285a.png

In this article, we will delve into common problems associated with SpO2 cables and how to troubleshoot them effectively.

Site

https://medke.usa18.wondercdn.com/uploads/image/63d7b0e4f285a.png

In this article, we will delve into common problems associated with SpO2 cables and how to troubleshoot them effectively.

Troubleshooting Common Issues with spO2 Cables

Views: 439

Author: Site Editor

Publish Time: 2023-10-13

Origin: Site

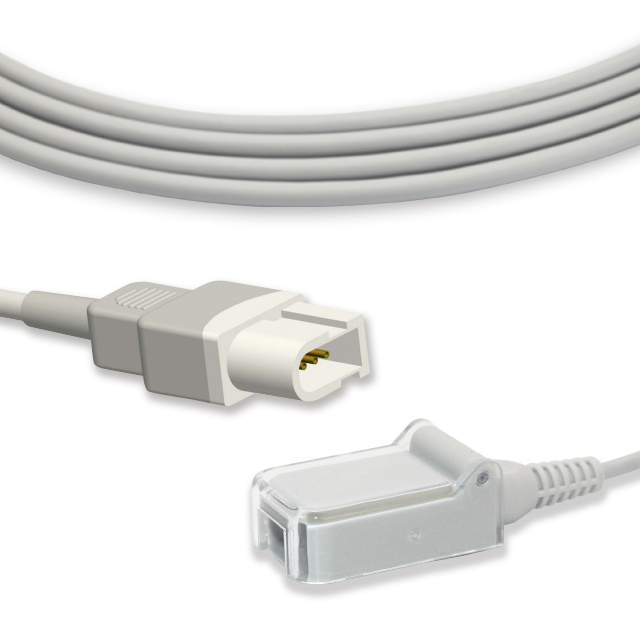

In the world of modern medicine, accuracy and reliability are paramount. One essential tool for monitoring a patient's oxygen saturation is the SpO2 cable. However, like any other piece of equipment, SpO2 cables are not immune to issues that can affect their functionality. In this article, we will delve into common problems associated with

SpO2 cables and how to troubleshoot them effectively.

Common Issues with spO2 Cables

Intermittent Readings

Intermittent readings can be frustrating and potentially dangerous when monitoring a patient's oxygen saturation. This issue is often caused by a loose connection or damaged cable. To troubleshoot, ensure that the cable connections are secure and inspect the cable for any visible damage.

Inaccurate Readings

Inaccuracy can lead to improper patient care and diagnosis. If your SpO2 cable is consistently providing incorrect readings, check for the following:

Position of the sensor: Ensure the sensor is correctly placed, typically on a patient's fingertip.

Environmental factors: Bright lights or excessive motion can interfere with the sensor's accuracy.

Calibration: Some SpO2 cables may require periodic calibration to maintain accuracy.

Cable Fraying

Over time, SpO2 cables can wear and tear, resulting in cable fraying. Inspect the cable for any visible damage, and if you find fraying or exposed wires, it's essential to replace the cable immediately.

Sensor Discomfort

Patients can experience discomfort from the SpO2 sensor. Ensure that the sensor is correctly placed and not too tight on the patient's fingertip. Additionally, use sensors with soft, hypoallergenic materials to minimize discomfort.

Compatibility Issues

Sometimes SpO2 cables are not compatible with certain patient monitors or equipment. Verify the compatibility of the cable with your specific monitoring equipment, and consult with the manufacturer if you encounter issues.

Troubleshooting Solutions

Now that we've identified common issues, let's discuss the solutions:

Regular Maintenance

Routine inspection and maintenance of SpO2 cables can prevent many issues. Keep the cables clean, free from entanglements, and securely connected. Check the cables for any signs of wear or damage.

Calibration

Calibrate your SpO2 cable regularly, as recommended by the manufacturer. This ensures accurate readings and extends the cable's lifespan.

Use Quality Accessories

Invest in high-quality SpO2 sensors and cables. Inferior accessories are more likely to cause problems. Medke, a trusted name in medical equipment, offers reliable and high-quality SpO2 cables that are compatible with a wide range of patient monitors.

Proper Placement

Ensure the SpO2 sensor is correctly placed on the patient's fingertip, avoiding excessive pressure. Educate your staff on proper sensor placement to minimize discomfort and inaccuracies.

Replacement

If your SpO2 cable is damaged or worn, replace it promptly. Using a compromised cable can lead to unreliable readings and jeopardize patient care.

Trust Medke for Reliable SpO2 Cable Solutions

In the world of healthcare, precision and reliability matter, and Medke is your trusted partner for high-quality SpO2 cables. Our commitment to delivering top-notch accessories ensures accurate patient monitoring and, ultimately, better patient care. When troubleshooting common issues with SpO2 cables, remember that you can rely on Medke for dependable solutions that enhance the quality of medical care.