News

Site Editor

Site

https://medke.usa18.wondercdn.com/uploads/image/63d7b0e4f285a.png

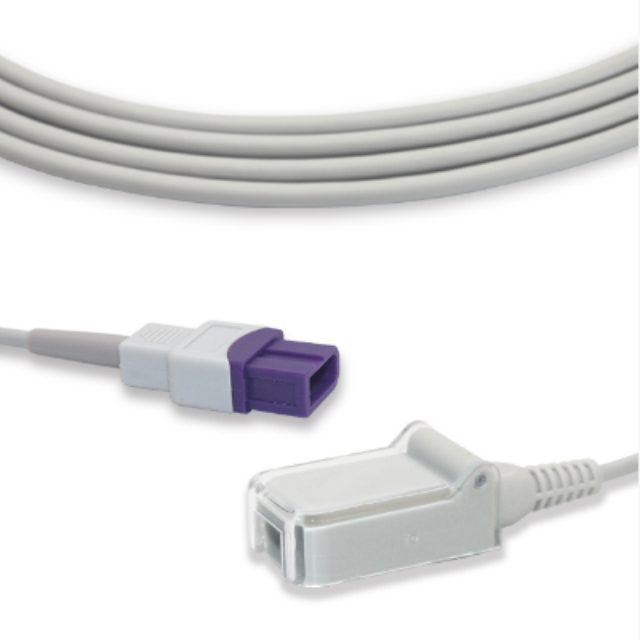

In this article, we will compare the different types of spO2 cables, shedding light on the advantages and disadvantages of each, to help you make an informed decision for your patient monitoring needs.

Site

https://medke.usa18.wondercdn.com/uploads/image/63d7b0e4f285a.png

In this article, we will compare the different types of spO2 cables, shedding light on the advantages and disadvantages of each, to help you make an informed decision for your patient monitoring needs.

Comparing Different Types of spO2 Cables: OEM vs. Aftermarket Cables

Views: 405

Author: Site Editor

Publish Time: 2023-09-22

Origin: Site

In the world of medical devices, precision and accuracy are paramount. When it comes to monitoring a patient's oxygen saturation, having a reliable spO2 cable is crucial. However, healthcare providers often face the choice between Original Equipment Manufacturer (OEM) spO2 cables and aftermarket alternatives. In this article, we will compare the different types of

spO2 cables, shedding light on the advantages and disadvantages of each, to help you make an informed decision for your patient monitoring needs.

OEM spO2 Cables: The Gold Standard

Precision and Compatibility: OEM spO2 cables are designed and manufactured by the original equipment manufacturer of the pulse oximeter. They are engineered to meet the device's precise specifications, ensuring seamless compatibility and accurate readings.

Quality Assurance: OEM cables undergo rigorous quality control and testing processes to meet industry standards. This ensures that the cable meets the highest quality and safety requirements.

Warranty Support: Purchasing OEM spO2 cables often comes with manufacturer-backed warranties, providing peace of mind and support in case of product issues.

Aftermarket spO2 Cables: Cost-Effective Alternatives

Affordability: Aftermarket spO2 cables are generally more budget-friendly than OEM cables. This can be an attractive option for healthcare facilities looking to reduce costs without compromising on quality.

Diverse Selection: Aftermarket cables come in various brands and configurations, allowing for more choices to suit specific needs and equipment.

Quick Availability: Aftermarket cables are readily available from multiple suppliers, often with faster delivery times compared to OEM cables.

Key Differences Between OEM and Aftermarket spO2 Cables

Quality Assurance: OEM cables are manufactured to the highest quality standards, ensuring precision and accuracy. Aftermarket cables may vary in quality, so careful selection of a reputable supplier is essential.

Compatibility: OEM cables guarantee compatibility with specific pulse oximeters, while aftermarket cables may require additional research to ensure they are suitable for your device.

Warranty: OEM cables typically come with manufacturer-backed warranties, while aftermarket cables may have varying warranty policies depending on the supplier.

Applications and Considerations

Critical Care Settings: In critical care environments where precision is paramount, OEM spO2 cables are often preferred to guarantee accurate readings.

Budget Constraints: Healthcare facilities with budget constraints may consider aftermarket cables to reduce costs, as long as they ensure the cables meet quality standards.

Trust Medke for Your spO2 Cable Needs

The choice between OEM and aftermarket spO2 cables depends on your specific needs, budget, and quality requirements. OEM cables offer unparalleled precision and compatibility, making them ideal for critical care settings. On the other hand, aftermarket cables provide cost-effective alternatives without sacrificing quality when sourced from reputable suppliers.

At Medke, we understand the importance of reliable spO2 cables in patient monitoring. We offer a range of high-quality spO2 cables that meet industry standards, ensuring accurate readings and compatibility with various pulse oximeters. Trust Medke for your spO2 cable needs and experience the highest level of precision and reliability in patient care.